Detailed Product Description

Introduction:

At present, there are kinds of methods for hardness measurement, commonly used like Brinell, Rockwell, Vickers, Leeb, etc. while the disadvantages are obvious for the above hardness measurement .Rockwell and Brinell with heavy loading force and big indentation, lead to serious destruction on sample surface.

Vickers apply optical measurement, but only professional technicians can operate smoothly, impossible to measure hardness of heavy work piece, installed machinery and permanently assembled parts.

Leeb hardness tester apply rebound and indirect method to measure hardness, easily lead to big deviation when convert to Birnell, Rockwell and Vickers scales.

Ultrasonic hardness tester UCI-100 apply ultrasonic contact impedance method to do comparative hardness measurement for testing pieces, with advantages of high accuracy, efficiency, portable and easy operation.

Ultrasonic hardness tester UCI-100 is widely used to measure hardness of small forgings, cast material, weld inspection, heat affected zone, Ion-nitrided stamping dies and molds, forms, presses, thin walled parts, bearings, tooth flanks, etc.

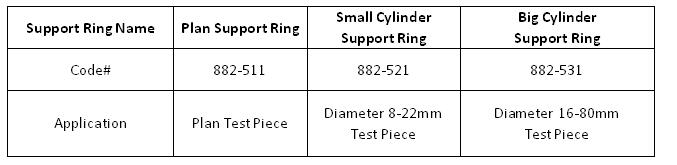

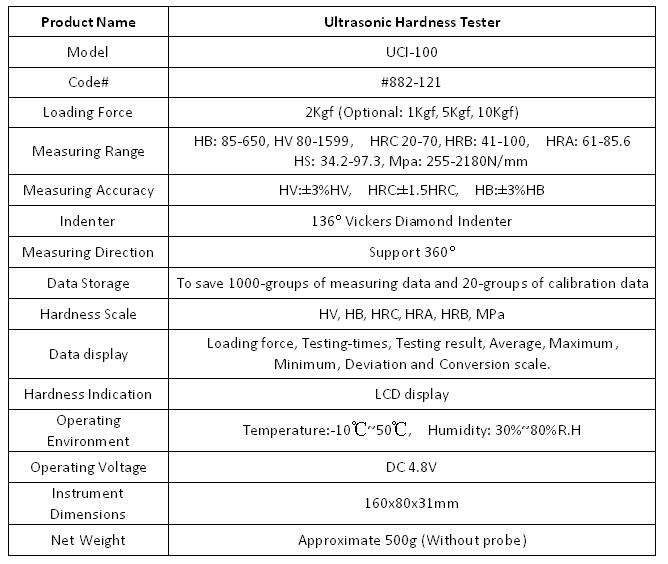

UCI-100 Specifications:

UCI-100 Specifications:

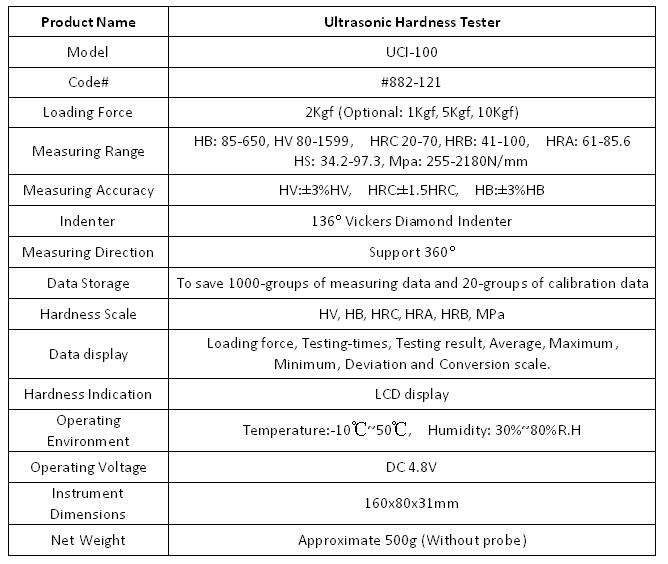

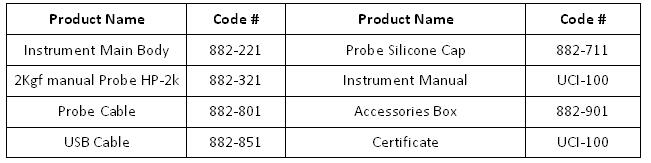

Standard Delivery:

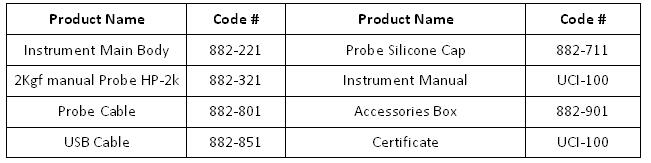

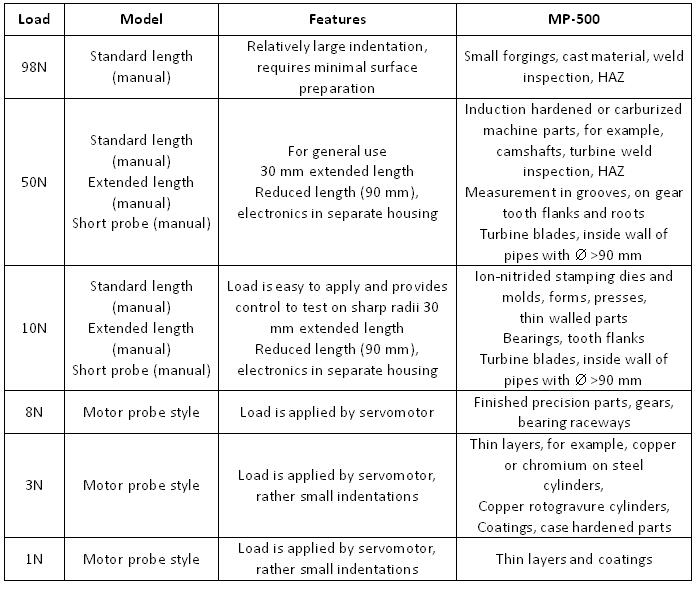

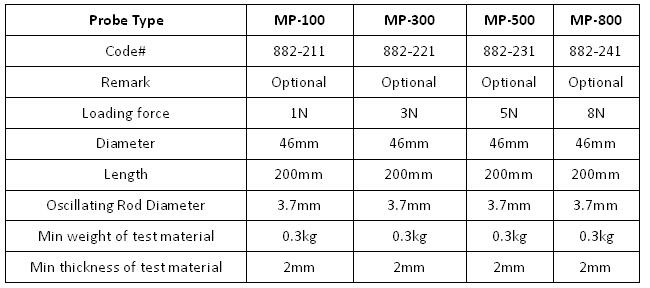

Manual Probe Specifications:

Manual Probe Specifications:

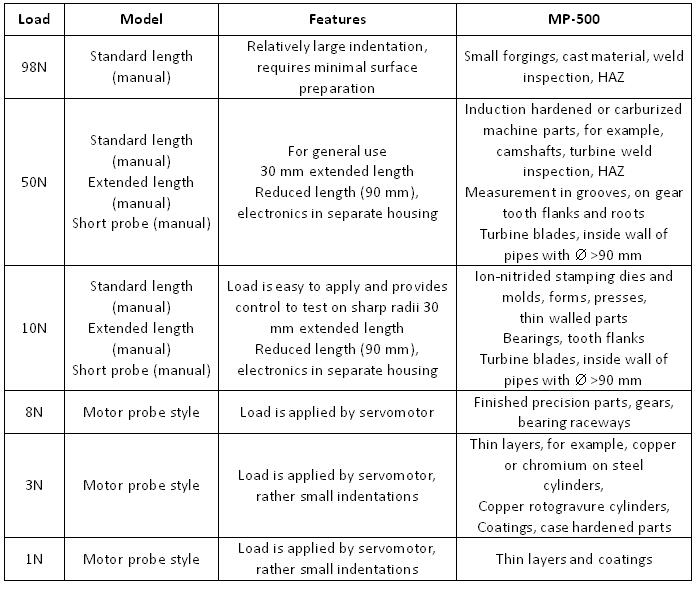

Motorized Probe Specifications:

Motorized Probe Specifications:

Guidelines for selection and use of UCI instruments

Block Specification:

Block Specification:

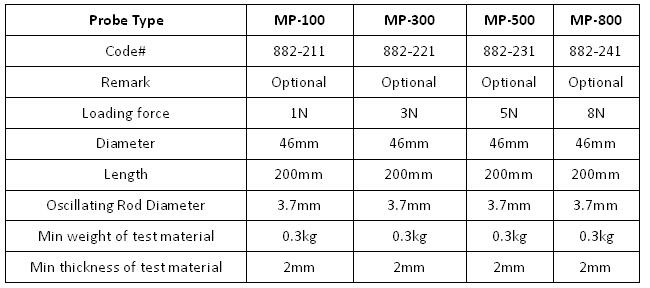

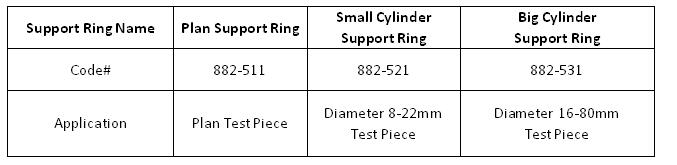

Support Ring Specifications:

Support Ring Specifications: