Detailed Product Description

Ultrasonic Flaw Detector UTS-300

Internationally-advanced digital integrated and artificial intelligence technology is adopted to launch a portable all-digital intelligent ultrasonic flaw detector UTS-300 which reaches the international standard.

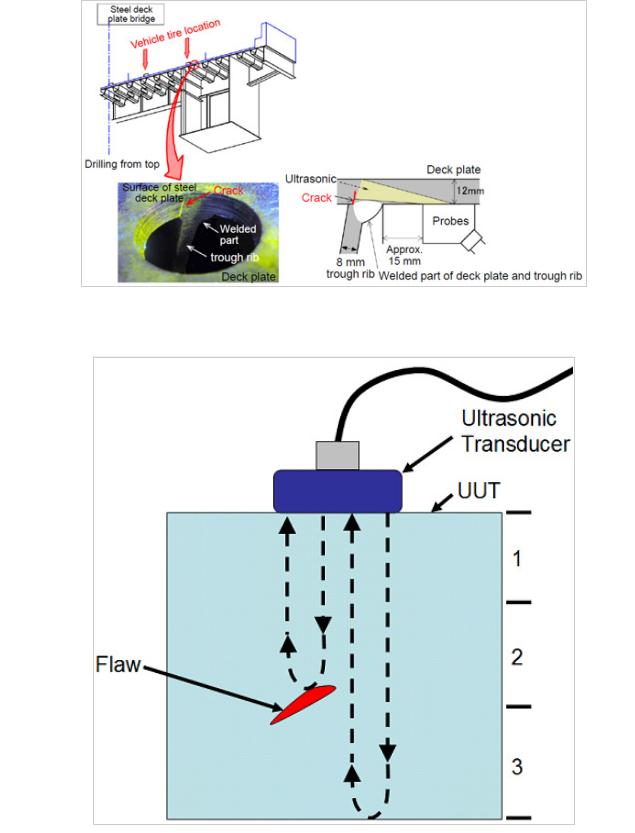

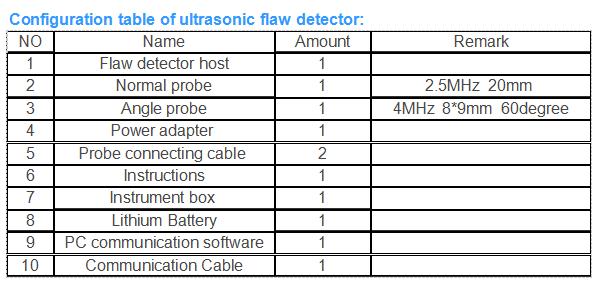

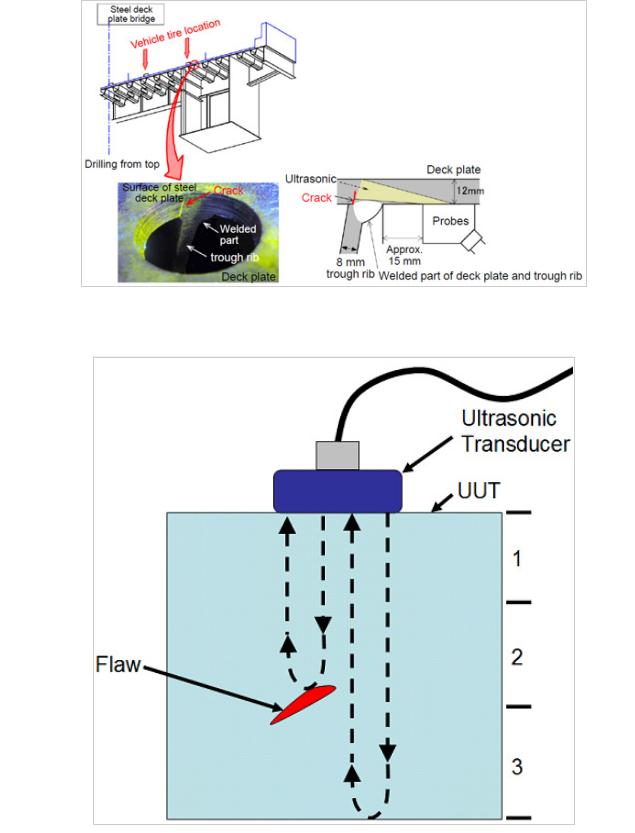

This instrument with full function and practical performance is applicable to detection of defects in all materials, for example, steel, copper, aluminum, hard alloy, casting, organic glass, composite material and welded joint, and is able to effectively defect defects, including air hole, crack, loose, mix, incomplete penetration and so on, it is a real notebook type digital ultrasonic flaw detector. Its application fields involve industries of aerospace, war industry, chemical industry, electric power, steel and iron, metallurgy, railway, train, motorcar, mechanics, security check, pipeline and construction.

Functional characteristics

High-speed scanning, ultra low noise, excellent property

Full metal jacket, beautiful and firm appearance, wonderful anti-disturbance performance

Abundant intelligent flow detection tools, simple and easy use

Powerful PC software, able to export flaw detection report in excel format

Flaw detection function

● Five measured value display areas, one of them is a major display area for amplifying display, 17 types of measured values are alternative

● Two independent gates may support independent measurement and joint measurement.

● File management system is adopted to realize dynamic data storage, 100 independent flaw detection channels, and 300 flaw detection reports including A scanning image.

● Automatic probe calibration function: ‘zero point’, ‘K value’, ‘front edge’ and ‘sound velocity’ of material.

● Intelligent DAC curve: the intelligent DAC curve can be calibrated in any sequence, automatically generated and made in sections, and revised and compensated; considered for material attenuation and surface compensation; offset curve can be adjusted randomly and in compliance with various domestic and international flaw detection standards; and provided with 6dB DAC function.

● AVG curve can be automatically generated and applied to find out the highest flaw wave and automatically convert value of aperture ф and automatically calculate large flat base.

● audible and visual alarm, and DAC alarm in gate

● IP65 standard aluminum magnesium alloy shell is firm, durable, water- and dust-proof, and excellent in immunity from interference.

● High-capacity secure and environment-friendly lithium ion battery may provide ultra-long standby time and more than 9h constant working time.

● It may communicate with the computer to realize computer data management and export flaw detection report of A4 paper in excel format.

Main technical indexes

Main technical indexes

Scanning range: (0-10000)mm

Pulse displacement: (-20~+3400) s

Probe zero point: (0.0~99.99)ms

Material sound velocity: (1000~15000 )m/s

Working form: single-probe, double-probe, and transmission probe

Frequency range: (0.5–20)MHz

Gain adjustment: (0~110)dB

Vertical linear error: ≤3%

Horizontal linear error: ≤0.2%

surplus sensitivity of flaw detection: ≥66dB (200mm depthФ2 bottomed hole)

Dynamic range: ≥32dB

Flaw detection channel: file management system is adopted to realize dynamic data storage, 100 independent flaw detection channels and 300 flaw detection report containing A scanning image.

Interface standard communicated with PC computer: RS232

Gate: two independent gates may support independent measurement and joint measurement.

Alarm: audible and visual alarm, and DAC alarm in gate

Power adapter Input: 100V~240V/50Hz~60Hz, output 9V/1.5A

Battery: lithium (Li) battery 4*3.6V 4800Ah

Operating temperature (℃): -10~50

Operating humidity (RH): 20%~90%

Overall dimension: 240×150×50(mm)

Gate alarm

Gate position, width and height can be adjusted randomly; and audible and visual alarm, and DAC alarm in the gate are extremely effective.

Data storage

File management system is adopted to realize dynamic data storage, 100 independent flaw detection channels, and 300 flaw detection reports containing A scanning image.

Recording function

Testing process real-time recording function

It adopts international advanced digital integration and artificial intelligence technology, introduced the international standard of portable digital intelligent ultrasonic flaw detector UTS-300.

The instrument can be used to detect internal defects of various materials, such as copper, aluminum, steel, hard alloy, casting, organic glass, composite materials, and weld, and so on, which can effectively detect air flow, cracks, porosity, inclusion, incomplete fusion, fully functional, practical, and is a real notebook digital ultrasonic flaw detector.Application areas involved in spaceflight, military industry, chemical industry, electric power, steel, metallurgy, railway, train, automobile, motorcycle, machinery, security, pipes, construction and other industry.