Detailed Product Description

The high resolution (800x480) 5 inch wide-screen color TFT screen, with visual reading habits, to achieve the best results, striking A-scan representation in any lighting condition. The HS720 SERIES is designed to meet the requirements of EN12668-1:2010 and allows a full range of standard and optional flaw detection features. Multiple on board reporting tools and a comprehensive data filing system enable you to easily collect and report high quality inspection data. The rugged, ergonomic design allows use in nearly any inspection environment, while the highest number of digital filters in its class can tackle nearly any application.

The HS720 SERIES Digital Ultrasonic Flaw Detector combines our industry leading conventional flaw detection capabilities with the efficiency of a highly portable, intuitive instrument. The HS720 SERIES flaw detector’s blend of efficient menus and direct access keys allows you to take advantage of the highest quality flaw detection platform with exceptional ease of use.

Designed for All Inspection Environments

The HS720 SERIES is designed for use in nearly any inspection environment, from bench top testing in a laboratory to extreme outdoor and hazardous conditions. Designed for IP rating in either knob (IP61) or navigation pad (IP62) configurations, and tested to very high environmental and reliability standards, the HS720 SERIES allows users in any inspection environment to feel confident in both the performance and durability of the instrument.

Summary

The HS720 SERIES portable digital ultrasonic flaw detector is a perfect collection of high-tech which is composed by ultrasonic flaw detector, ultrasonic thickness gauge, ultrasonic though coating thickness gauge, computer, electronics, mold, technology and other modern high-tech. It provides the industry with superior performance, and more powerful digital ultrasonic flaw detector.

Key Features

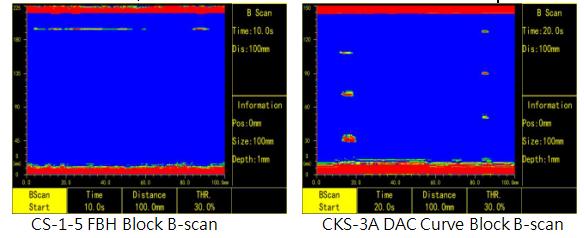

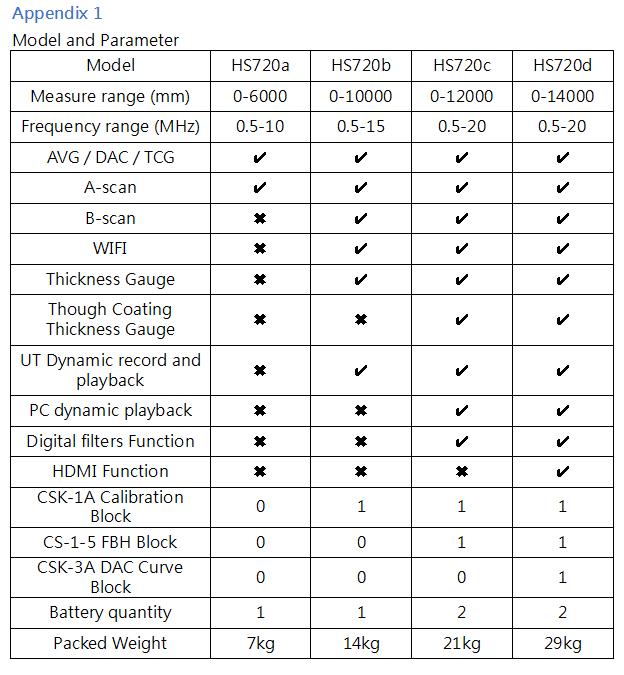

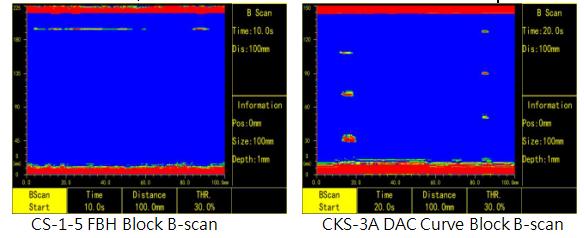

• Colurful B-scan

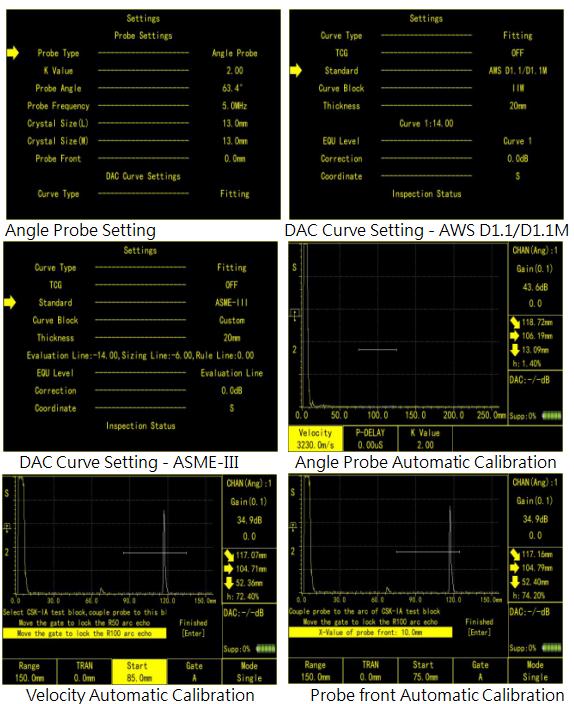

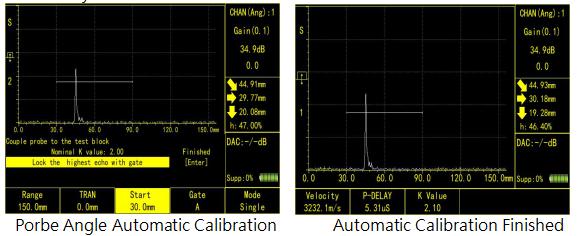

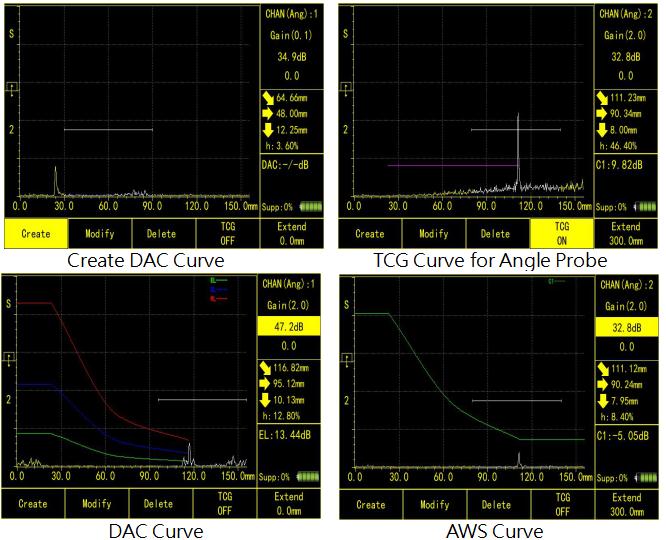

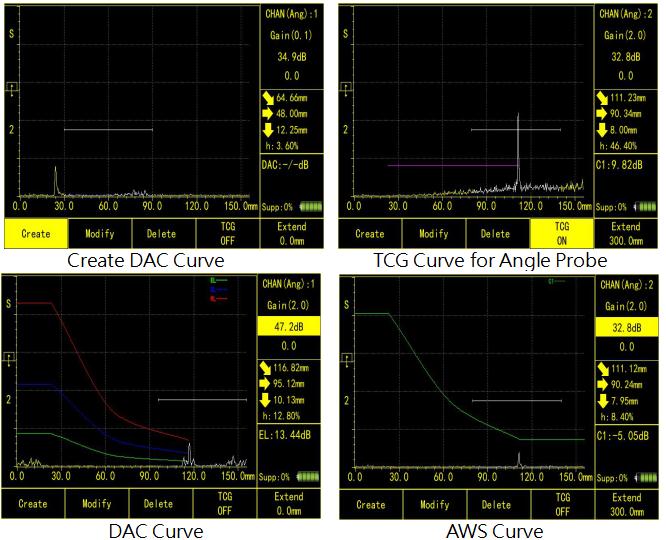

• DAC, AVG, TCG

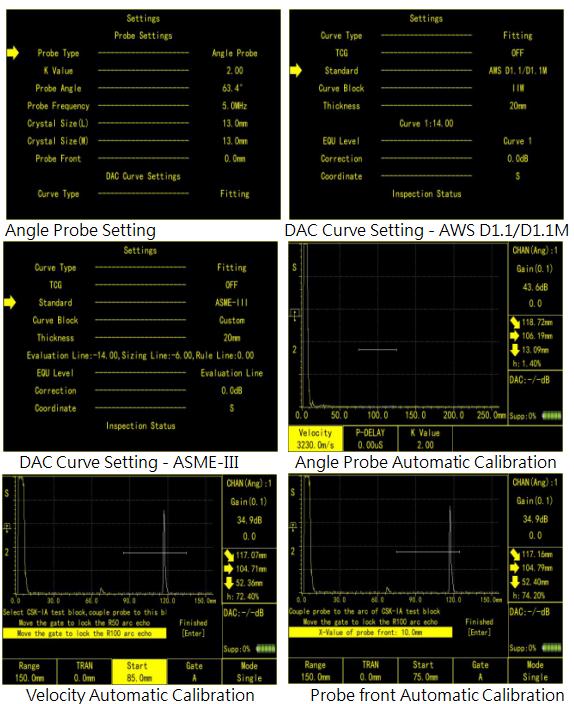

• Meet EN12668-1:2010

• Size: 80 x 130 x 40mm

• Weight: 1 kg with battery

• Tunable square wave pulser

• Build-in 4.1 mm thickness block

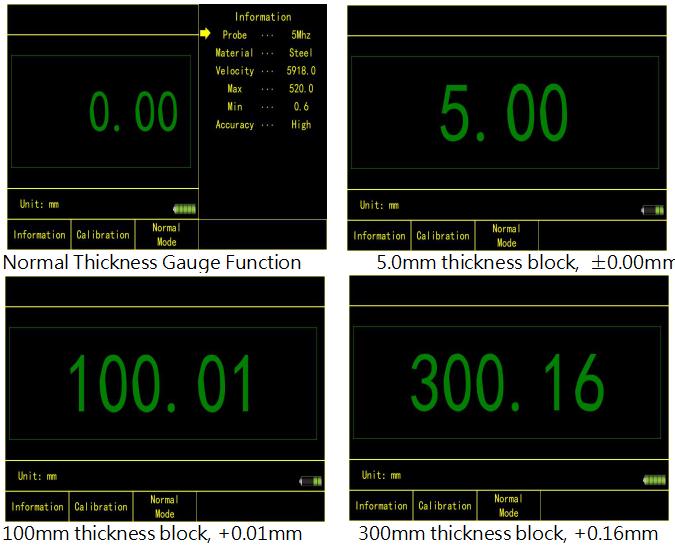

• Build-in ultrasonic thickness gauge

• Build-in though coating thickness gauge

• 10 hours of battery life, import from Japan

• Suit for 2mm thickness work-piece inspection

• Digital filters for enhanced signal-to-noise ratio

• 5inch 800x640 full TFT screen, import from South Korea

• 1G internal memory can storage the record for 30 hours.

• 16G TF memory card with inside offline analysis software

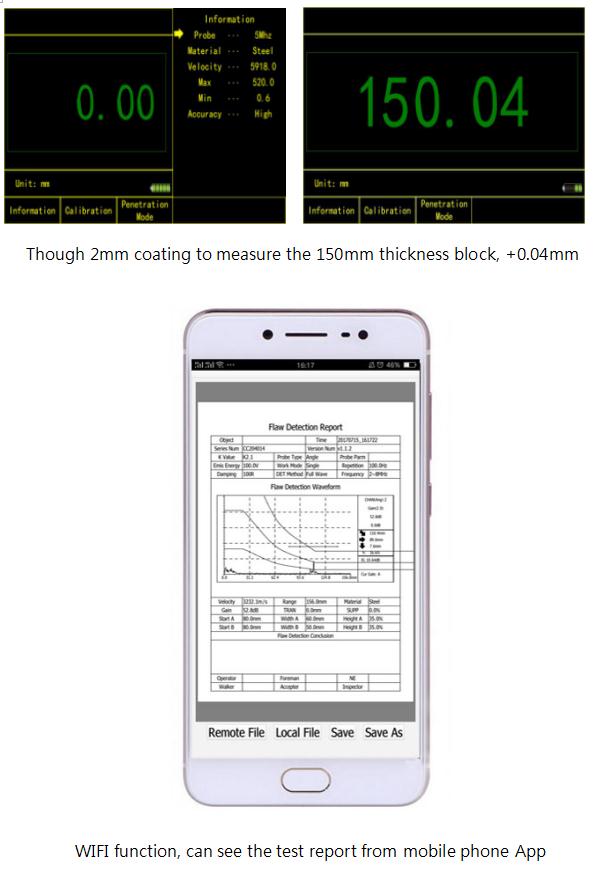

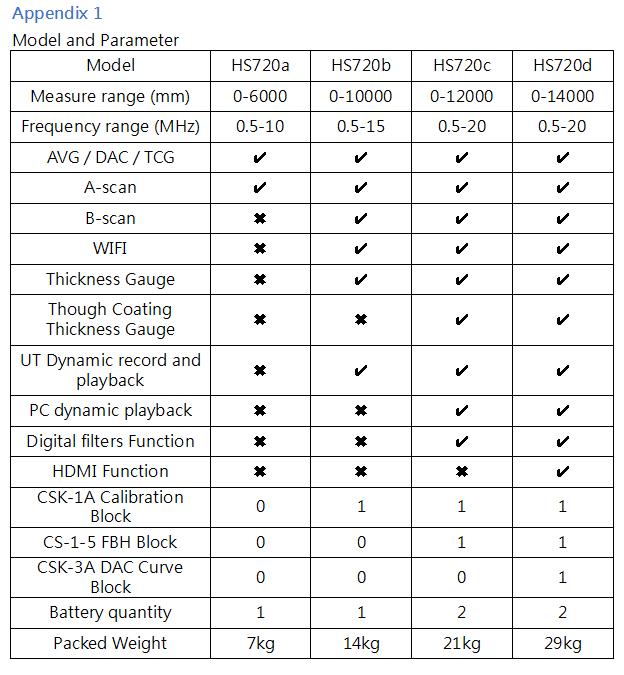

• WIFI function, can see the test report from mobile phone App

• ASME, AWS D1.1/D1.1M and all international Standards include

• CPU / Chip / Diode are import from the USA, Korea and Japan

• HDMI interface can connect the monitor or projector for any training

• Independent PC dynamic playback software, can fast forward and slow release.

Details features:

Details features:

1.Hand held structure, beautiful, firm, good sealing performance, strong anti-interference ability.

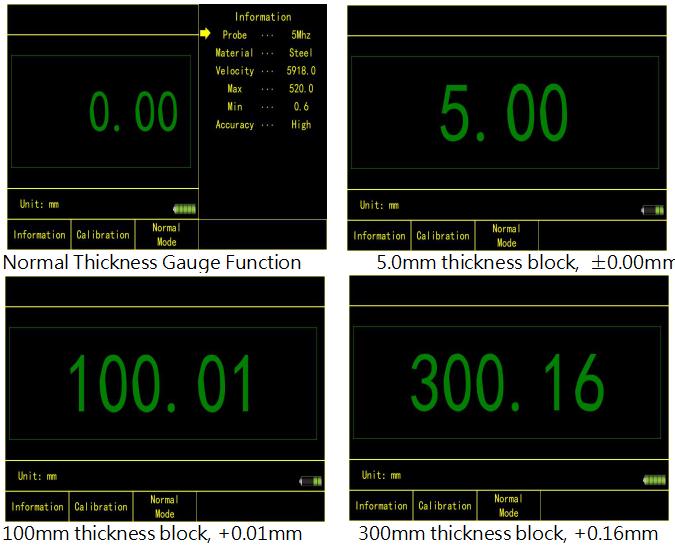

2.Build-in ultrasonic thickness gauge, 0.01mm resolution, 0.75-600mm measuring range, suitable for any frequency ultrasonic probes

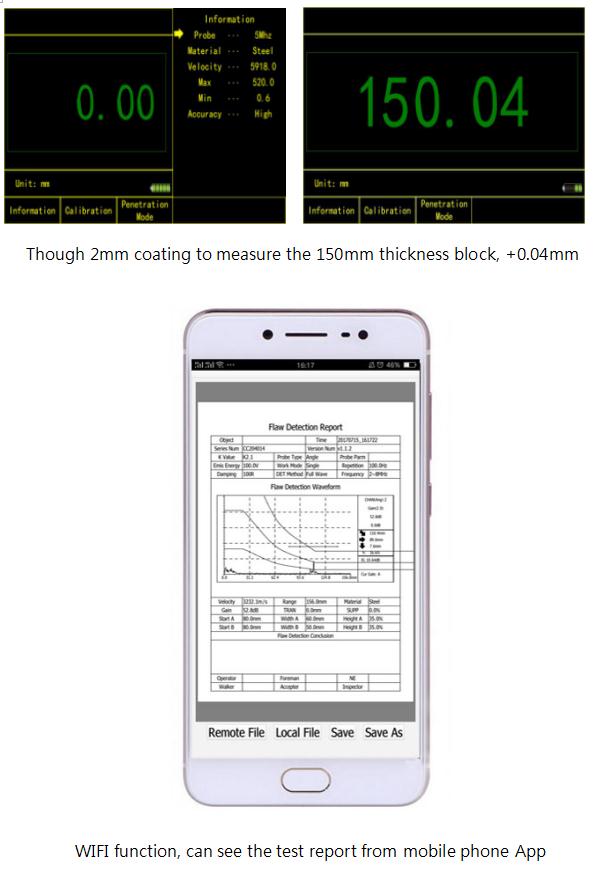

3.Build-in though coating ultrasonic thickness gauge, 0.01mm resolution, can though 10mm coating or painting to measure 2mm to 150mm thickness.

4.High resolution (800x480) 5 inch wide-screen color TFT LCD screen, with visual reading habits, to achieve the best results.

5.Small size - the size of the overall size of the machine is 180 x 130 x 40mm.

6.Light weight - the weight of the whole machine including the battery is 1 kg.

7.Digital filter function can remove the clutter function in the detection of the coarse grain materials.

8.16G TF card can achieve data storage and transfer.

9.Easy operation. Calibration and curve making process have clear operation prompt which can help us master the operation of the instrument without specification.

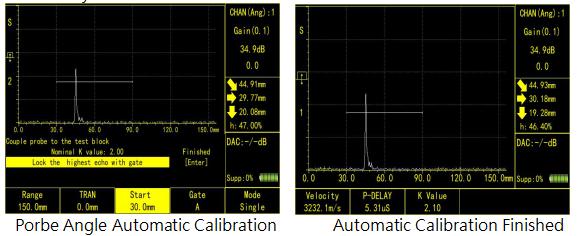

10.The instrument is built in a number of national standards which make it easily to set a variety of DAC, AVG, TCG curve parameters.

Main parameters for Ultrasonic Flaw Detector

Transmit pulse: Square wave. Emitter voltage of 25V - 400V continuously adjustable, Stepping 25V Continuously adjustable width 30ns - 1000ns, Continuously adjustable width 30ns - 1000ns,Stepping 5ns.

Work type: Single, double.

Impedance matching: 50Ω, 100Ω, 150Ω, 400Ω.

Band select: Divided into 0.5-4MHz, 2-8MHz, 0.5-20MHz three.

Gain Range: 0.0-110.0dB (step 0.1dB, 1.0dB, 2.0dB, 6.0dB adjustable).

Detection range: 2.0 - 10000mm (longitudinal wave in steel). Continuously adjustable.

Detection methods: the positive half wave, negative half wave, full-wave, RF.

Pulse shift: -45 - 9999mm.

Probe zero value: 0 - 999.99μs.

Pulse repetition frequency: 25 - 1000Hz, manual adjustment mode.

Vertical linearity error: ≤3%

Level linearity error: ≤0.3%.

Sensitivity margin: > 60dB (200Φ2 flat bottom hole)

Resolution: > 36dB.

Dynamic Range: ≥32dB.

Rejection: (0-99) %, does not affect the linearity and gain.

RF output impedance: 50Ω.

Electrical noise level: <10%.

Interface: BNC 9mm instrument interface

Power: (two power supply): - high-capacity lithium battery, no memory effect, continuous work more than eight hours. - 220V AC (with adapter).

Ambient temperature: -10 ℃ - 40 ℃.

Relative humidity: (20-95) % RH

Main parameters for Ultrasonic Thickness Gauge

Display resolution: 0.01mm

Measurement cycle 10 times / second

Sound Velocity Range: 1000m/s-9999m/s

Work-piece surface temperature: - 20℃ to 500 ℃

Optional probe: 2/5/7/10 MHz probe and high temperature probe

Measuring range: 0.75mm-300.0mm (Measuring range depends on probes, materials and conditions)

Accuracy: ±(0.5%Thickness+0.04)mm, depends on Materials and conditions

Data Memory: No limited stored values

Sound velocity: the instrument contains 9 kinds of sound velocity, the user can directly call or customize the sound velocity.

Main parameters for Ultrasonic Though Coating Thickness Gauge

Display resolution: 0.01mm

Maximum coating thickness: 2mm

Measuring thickness range: 2-150mm (Special 5MHz 10mm)

Work-piece surface temperature: - 20℃ to 60 ℃

Accuracy: ±(0.5%Thickness+0.04)mm, depends on Materials and conditions

Data Memory: No limited stored values

Sound velocity: the instrument contains 9 kinds of sound velocity, the user can directly call or customize the sound velocity.

Standard Configuration for HS720a Ultrasonic Flaw Detector

Standard Configuration for HS720a Ultrasonic Flaw Detector

1 Main Body, with BNC 9mm Connector 1

2 Straight Beam Probe 2.5MHz 20mm, BNC connector 1

3 Angle Probe 5MHz, 13*13mm, K 2.0, BNC connector 1

4 Machine-probe Cable BNC 9mm to BNC 9mm 2

5 Lithium Battery Module 11.8V 5200mAh 1

6 Power Adapter (Charger) 19V 4.74A 1

7 16G TF memory card with inside offline analysis software 1

8 European standard performance test report 1

9 Instruction Manual, Packing List, Warranty Card, Quality Certificate 1

10 Import Quality Carrying case with Environmental protection foam inserts 1

Standard Configuration for HS720b Ultrasonic Flaw Detector

1 Main Body, with BNC 9mm Connector 1

2 Straight Beam Probe 2.5MHz 20mm, BNC connector 1

3 Angle Probe 5MHz, 13*13mm, K 2.0, BNC connector 1

4 Machine-probe Cable BNC 9mm to BNC 9mm 2

5 Lithium Battery Module 11.8V 5200mAh 1

6 Power Adapter (Charger) 19V 4.74A 1

7 16G TF memory card with inside offline analysis software 1

8 European standard performance test report 1

9 Instruction Manual, Packing List, Warranty Card, Quality Certificate 1

10 Import Quality Carrying case with Environmental protection foam inserts

11 BNC to Lemo 00 Conversion Connector 2

12 5MHz 10mm ultrasonic thickness gauge probe 1.2-225mm 1

13 CSK-1A Calibration block 1

Standard Configuration for HS720c Ultrasonic Flaw Detector

1 Main Body, with BNC 9mm Connector 1

2 Straight Beam Probe 2.5MHz 20mm, BNC connector 1

3 Angle Probe 5MHz, 13*13mm, K 2.0, BNC connector 1

4 Machine-probe Cable BNC 9mm to BNC 9mm 2

5 Lithium Battery Module 11.8V 5200mAh 2

6 Power Adapter (Charger) 19V 4.74A 1

7 16G TF memory card with inside offline analysis software 1

8 European standard performance test report 1

9 Instruction Manual, Packing List, Warranty Card, Quality Certificate 1

10 Import Quality Carrying case with Environmental protection foam inserts

11 BNC to Lemo 00 Conversion Connector 2

12 5MHz 10mm ultrasonic thickness gauge probe 1.2-225mm 1

13 Connect cable for though coating thickness gauge use 1

14 Ultrasonic though coating thickness gauge probe 2-150mm 1

15 CSK-1A Calibration block 1

16 CSK-1-5 FBH Block 1

Standard Configuration for HS720d Ultrasonic Flaw Detector

1 Main Body, with BNC 9mm Connector 1

2 Straight Beam Probe 2.5MHz 20mm, BNC connector 1

3 Angle Probe 5MHz, 13*13mm, K 2.0, BNC connector 1

4 Machine-probe Cable BNC 9mm to BNC 9mm 2

5 Lithium Battery Module 11.8V 5200mAh 2

6 Power Adapter (Charger) 19V 4.74A 1

7 16G TF memory card with inside offline analysis software 1

8 European standard performance test report 1

9 Instruction Manual, Packing List, Warranty Card, Quality Certificate 1

10 Import Quality Carrying case with Environmental protection foam inserts

11 BNC to Lemo 00 Conversion Connector 2

12 5MHz 10mm ultrasonic thickness gauge probe 1.2-225mm 1

13 Connect cable for though coating thickness gauge use 1

14 Ultrasonic though coating thickness gauge probe 2-150mm 1

15 HDMI communication cable 1

16 CSK-1A Calibration block 1

17 CS-1-5 FBH Block 1

18 CSK-3A DAC Curve Block 1

Optional accessories:

1 Any standard blocks

2 Any ultrasonic flaw detector probes

3 Any ultrasonic cables

4 Any thickness gauge probe

5 Extra battery

6 Third party test report