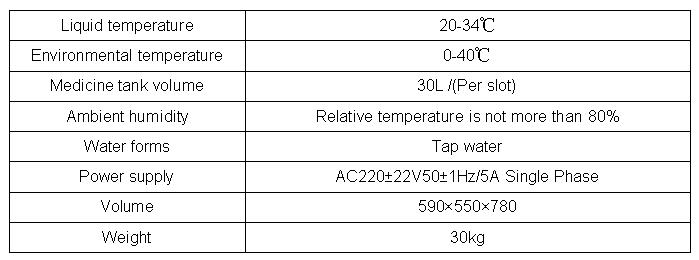

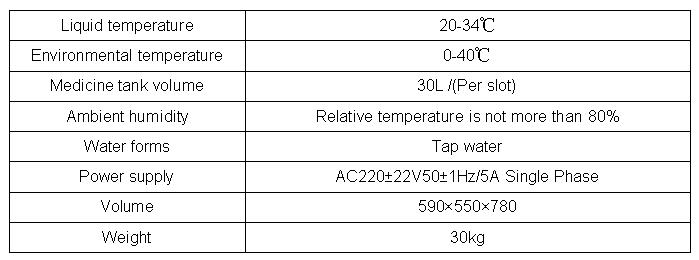

The main technical performance parameters:

Industrial Developing BucketManual installation

First, install the debugging

1.open the packaging, check whether the body injury.

2.the inlet connected to the water faucet on, and then fixed, and regulation of water flow is less than 2 liters / minute.

3.will drain into sewers.

4.Check Fixation Drainage ,Develop Drainage, drain valve, so that they are turned off.

5.respectively, in the developing tank and fixing tank preparation of 5 gallons (20 liters) of liquid.

6.plug in the power 220V10A.

7.will be the main liquid temperature adjustment knob to working temperature, Open the power supply, power indicator light, while heating bright light, such as adjusting the temperature reached when the lights out (that is liquid at a constant temperature condition) To make a film.

Second, the replacement of liquid

1.first turn off the power switch

2.open the valve developing, such as developing waste water discharge to do, clean water and developing a barrel after closing the valve developing , with a view to the preparation of re-imaging solution.

3.drainage valves open, two in a bucket of water every row, two buckets and cleaning after the closure of the drainage valves.

4.scheduled to open the valve row, Pai will be connected to the pump power switch, Fixing liquid waste will be discharged into the collection bins. Re-use water to clean fixing barrel, after closing the set of efflux pump power switch row and set the valve, in order to re-fixing liquid preparation.

Notes:

1.First, Emissions develop liquid (fixation liquid) before the closure of the heating liquid power switch.

2.Second, Developing barrels and fixation barrels per day in non-fixing solution, the solution to prohibit access to the heating power switch.