|

Measuring Principle |

Magnetic induction & Eddy current. With different external probes, the gauge can be applied to measuring thickness of non-magnetic coating on magnetic Metal substrate, as well as Non-conductive coating on non-magnetic metal substrate |

|

Measuring Range |

(0~1250) μm, depends on probes. maximum 10mm for the probe F10 |

|

Low Range Resolution |

0.1μm |

|

Accuracy |

±(3%Thickness+1) μm, depends on probes and conditions |

|

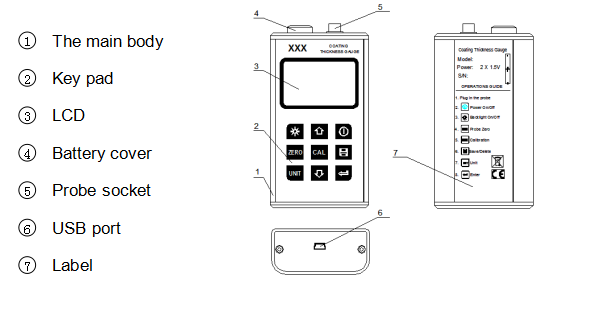

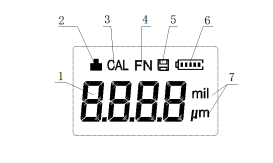

Display |

Digital LCD with EL backlight |

|

Storage |

Memory for up to 20 files (up to 50 values for each file) of stored values |

|

Unit System |

Metric (μm)、Imperial (mil) |

|

Power Source |

Two “AA” size, 1.5 Volt alkaline batteries |

|

Working Hours |

200 hours typical operating time (EL backlight off) |

|

Communication |

USB1.1,can connect to PC |

|

Dimensions |

125mm×67mm×31mm |

|

Net Weight |

340g |