Detailed Product Description

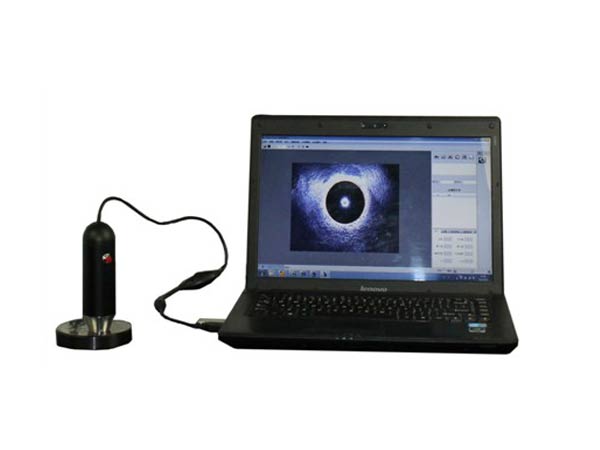

LHBS-MA-P by means of the techniques such as optics, electronics, computer and image analysis, specially used to automatically test the Brinell hardness values.

Features:

1. Easy portable: Whole system with small size and

exquisite design is easy to install and simple to operate.

2. Professional optics design: Assure the Brinell indentation

with clear image and sharp edge.

3. High resolution and digital image formation: Adopt the industry type and

digital camera head to enable the image clearly.

4. Accuracy analysis of image: Synthesize the shape, brightness and calculation of

edge to increase the accuracy of test results.

5. Highly test speed: Automatically test and calculate the accurate hardness value

and indentation diameters in real time.

6. Widely usage range: Test in laboratories or industrial workshop for polished

work-pieces or rusted and corroded specimens to get the accuracy results.

7. Strong software functions: Single piece test, series test, hardness exchange

according to Chinese Standard/ASTM, data and image storage, database

enquiry, alarming for unqualified hardness values and supporting SPC

program.

Main Functions:

1. Capturing Images: Real time display image of hardness indentation; store and

print its image.

2. Measuring Indentation: Automatically measure the indentation with good

repeatability, high accuracy and wide usages. At the same time, the system also

support to manually measurement and adjustment.

3. Calibrating method: Calibrate with standard hardness test blocks or length

scales.

4. Hardness exchanging: According to GB/ASTM standard, automatically

exchange the hardness value among the multiple hardness scales such as Brinell,

Rockwell, Vickers, etc.

5. Drawings and texts report: Automatically record the test data and output the

Word form report according to user’s stipulated requirement.

6. Data Output: Automatically record the test data and save the data with

EXCEL form.

7. Database supporting: Support the database so as to easy user’s enquiry.

Main Functions:

1. Measuring range: From 1.2mm to 6mm

2. Digital image formation: 1.3 mega-pixels industrial digital camera head.

3. Test method: Automatically / manually

4. Calibrating method: Standard hardness test blocks / length scales

5. Support language: Chinese / English

6. Power Supply: USB power supply

7. Weight: 0.5 Kg.