I.

Application

Industrial video endoscope (also known as view mirror) is a branch of nondestructive testing, and is also a special detection technique. Suitable for high temperature, toxic, nuclear radiation and the human eye cannot directly observe the site inspection and observation (such as: automobile, automobile casting, engine, machine parts, pipes, pressure vessels, power system, wind power generation, chemical, mechanical equipment, railway locomotives, etc.) can be realized without disassembly or in nondestructive testing destroy the assembly and equipment stop operation, can greatly improve the safety and efficiency of detection equipment.

I.

Main function and characteristics

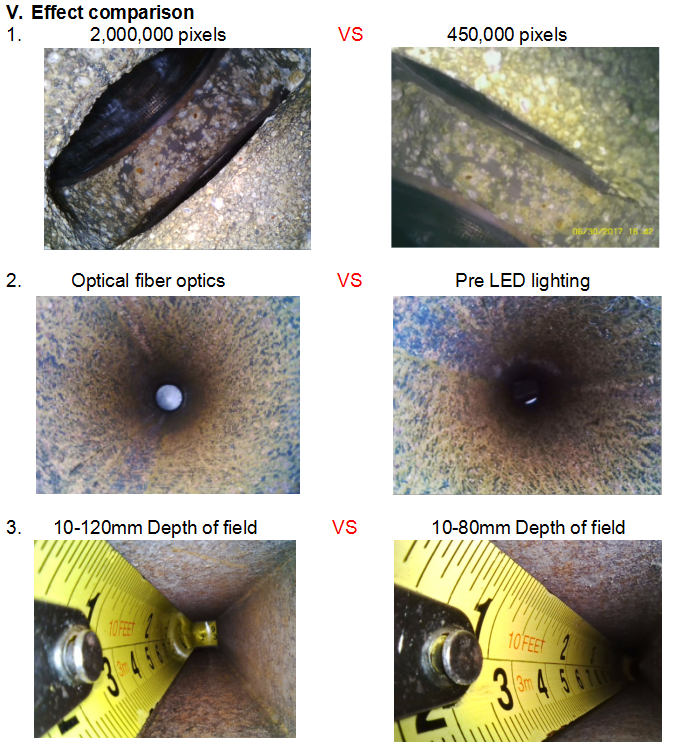

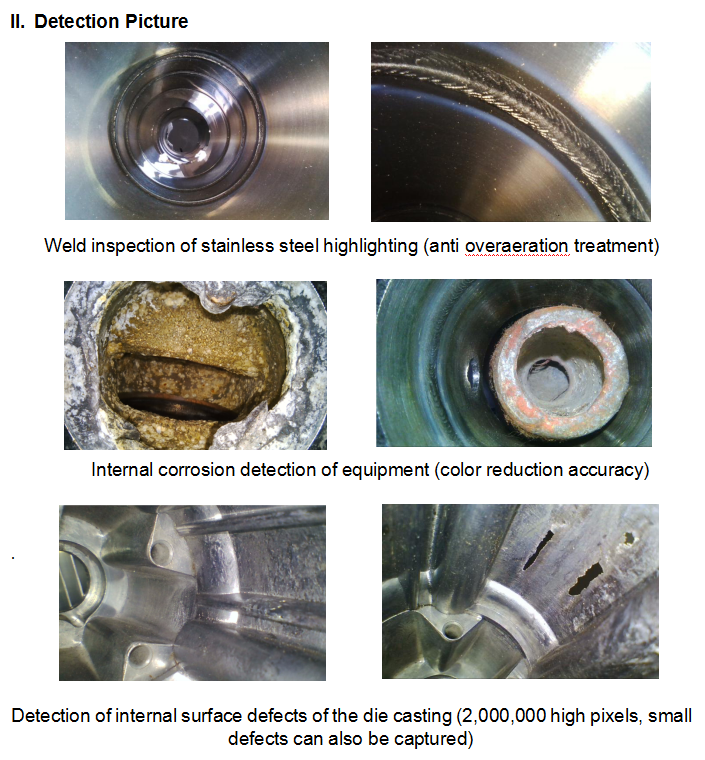

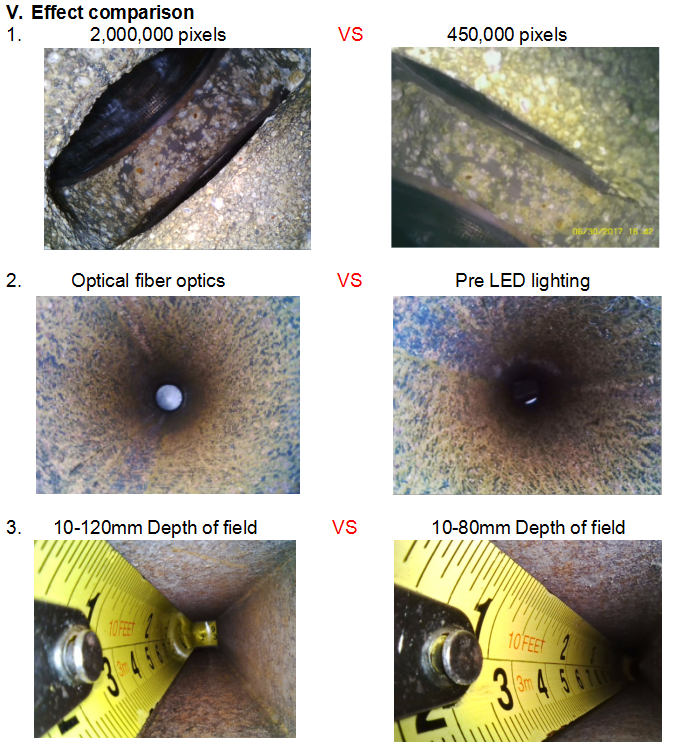

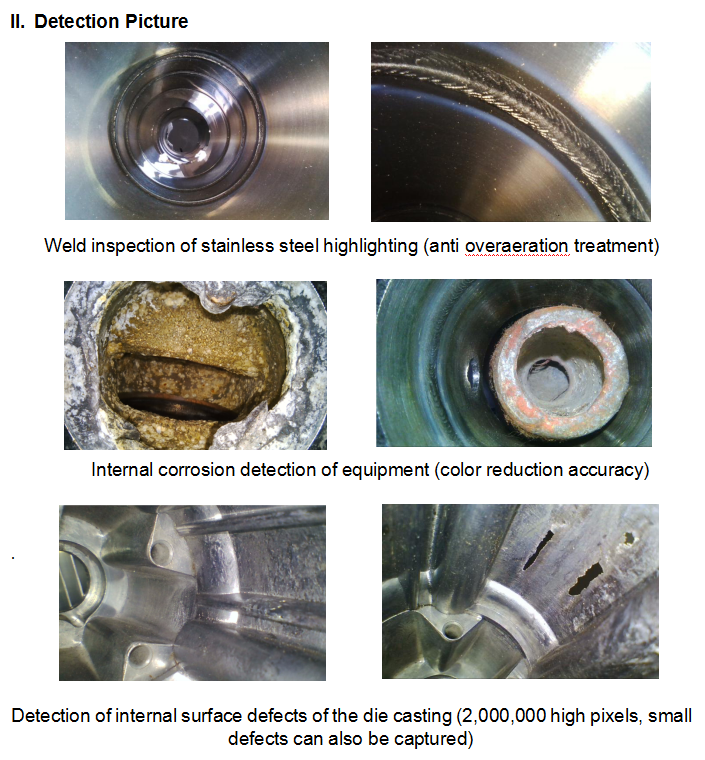

1. High definition: The insert probe diameter is 6mm - 2,000,000 pixels, and the insert probe diameter is 2.8/3.9mm-100 ten thousand images.

2. In the external 27 inch display no noise.

3. Front-end bright: Pre - optical fiber guide, 8 level brightness adjustment, even farther and more uniform.

4. Oversize depth of field: 5-200mm, 10-120mm Oversize depth of field.

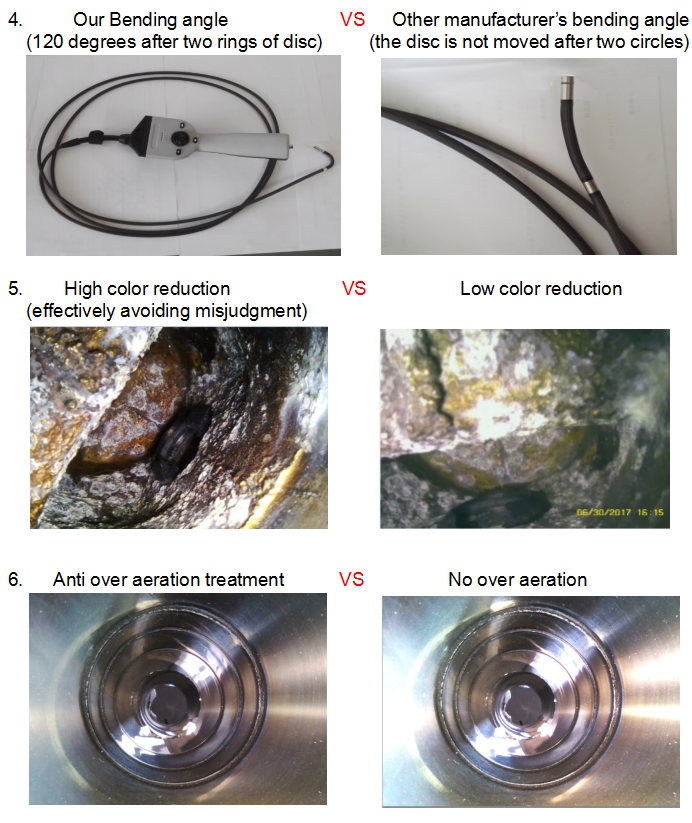

5. High precision: Mechanical guidance, 360 degrees of arbitrary rotation, control precision 0 delay.

6. Intelligent software: Support / rename, defect identification, English fast film, camera settings etc.

7. Optidur NC: Four layers of tungsten wire braiding probe, waterproof, wear-resistant and anticorrosion.

8. Super endurance: The battery can be replaced more than 8 hours of continuous work.

9. Flexible use: External computer / tablet / IPC real line on-line detection (with our E series endoscope operating software)