It is also called ring probe with an internal diameter of 150mm and center field ≥180Oe.Weight:2.5kg. It is designed on the principle of forming a strong magnetic field by energizing a coil and is suitable for sectional fault detection or demagnetization of complicated work pieces including axles, bars, pipes and vanes.

►E type probe:

It is also called cross magnetic yoke probe or rotating-field probe. Different from D-shaped and A-shaped probe, it can conduct omnibearing magnetization flaw detection at a time. The equipped working lamp ensures users to work with enough light; the equipped roller ensures easy operation and high working efficiency.

Polar distance: 110mm, hoisting capacity: AC≥12kg and weight:3 kg.

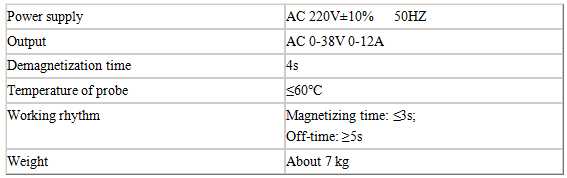

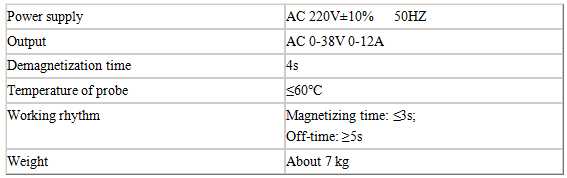

II.Main technical parameters

III.Cautions

1) The suggested working rhythm under long continuous working: Magnetizing time: ≤3s; Off-time: ≥5s

2) Before using, check the power supply, make sure it conforms to the standard requirements, avoid incorrect

defecting results caused by higher or lower voltage;

3) Make sure the probe surface should be well connected with the work piece, then power on magnetization, under

this condition, the magnetization effect is the best;

4) Avoid no-load working state;

5) This device can work continuously for a long time, during which if there is serious heat, user should stop this

machine;

6) The device should be kept in clean, dry and no-corrosive environment;

7) Pay attention to the high-voltage danger inside of this device when fixing;

8) The device should be well grounded.