Detailed Product Description

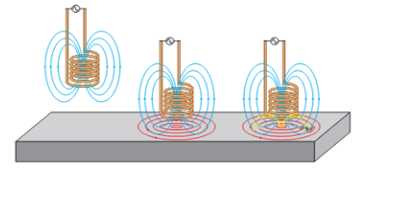

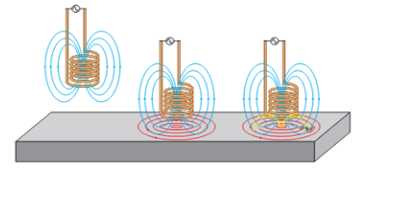

I.Eddy Current testing principle

Signal generating circuit generates alternating current supply detection coil; coil of the alternating magnetic field in the workpiece sense of eddy current and eddy current by test pieces of material or defects in turn affect the coil impedance change; amplifying circuit first detection coil obtain the detection of weak signal is large; and then through the signal processing circuit to eliminate disturbance to the impedance change and identify the "defects" effect; and finally show the test results.

II.The detection system overview

Eddy current testing equipment mainly includes:

II.The detection system overview

Eddy current testing equipment mainly includes: eddy current probe, eddy current testing instrument, auxiliary device and marking alarm device.

The effect of the eddy current probe: the eddy current is induced in the specimen and the eddy current signal with the mass information of the specimen is measured;

The role of the eddy current testing instrument: to detect the coil to provide alternating current and from the measured signal with a large number of information to identify the existence of the "defect";

Auxiliary device function: the completion of the work of saturation magnetization and other functions;

Precision purifying AC regulated power supply: has the advantages of high precision voltage regulation, high overload capacity, good reliability, strong anti-interference ability, high efficiency and quick response, and can effectively inhibit the power grid peak voltage and noise interference, anti electromagnetic interference ability is strong;

Installation location requirements: it is recommended to install in the back of the tank, on both sides of the pressing wheel to ensure smooth steel tube.

III. Technical performance of the system

We can detect the save and print records;

Have data backup and replay function;

Double channel probe, differential probe detecting short, mutation defects, absolutely probe is used to detect longitudinal corrosion and cracking defect;

10 repeat stability is 2dB;

Meet the test standard: GB/T7735-2004< steel pipe eddy current testing method for >B class.

IV.Eddy current testing machine technical index

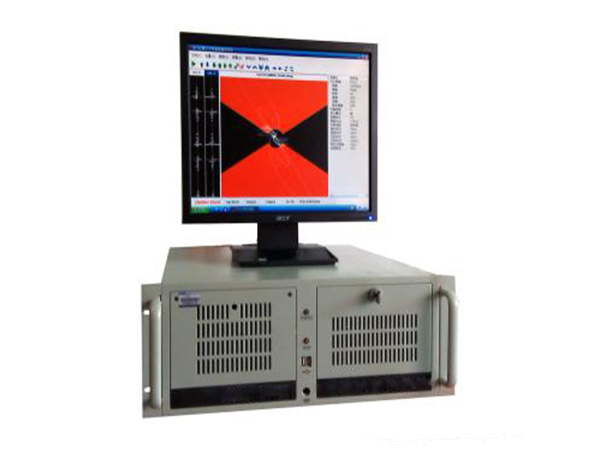

4.1 Instrument overview

ET20 digital intelligent eddy current flaw detector is a new generation of eddy current nondestructive testing equipment. It adopts imported large scale integrated circuit, combined with the most advanced digital electronic technology, eddy current technology and microprocessor technology, can real-time detect ferromagnetic and non ferromagnetic metal pipe inner wall and the outer wall defects. ET20 adopts advanced eddy current impedance plane and timebase technology design, in both Chinese and English menu man-machine conversation display, large screen signal, multi mode alarm technology and specially designed digital electronic balance technology, the instrument operation easier and more reliable.

4.2 The instrument technical index

Two independent detection channels

Frequency Range: 64 Hz ~ 5 MHz

Gain: 0~90dB,Step distance 0.5dB

Phase rotation:0~360 ° Step distance 1 °

Gain ratio(Y/X): 0.1~10

High pass, low pass, band pass filter, the bandwidth of 0 ~ 10KHz arbitrary adjustment, the minimum accuracy of 0.1Hz

The inspection highest speed 160 meters per minute

The internal and external clock control

High precision real time, time delay alarm, marking output

4.3 Introduction of probe

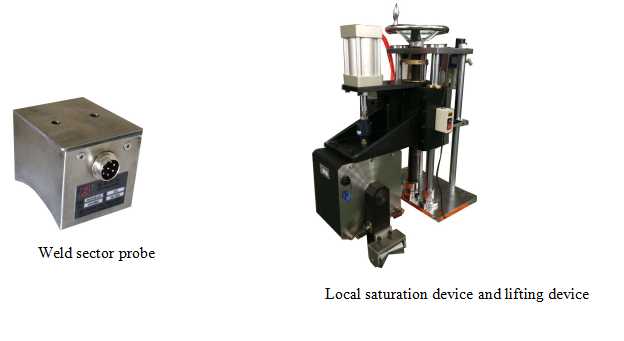

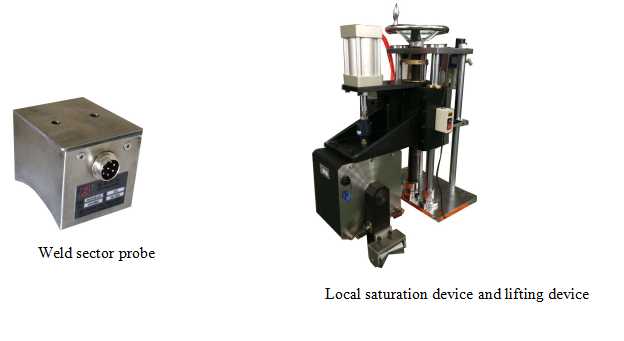

Special sector probe for weld seam: special purpose for steel tube partial detection, which is required to detect the position of the weld on the top.

Features: fan coil form suitable for inspection of pipe weld, in view of the strong detection with high sensitivity, suitable for production line for continuous, fast detection speed, easy to realize automatic inspection, especially for examination for metallurgical products in large quantities.

4.4 Auxiliary device introduction

Magnetic saturation device

4.4 Auxiliary device introduction

Magnetic saturation device

(1)The reason for applying magnetic saturation

Ferromagnetic metal after cold processing, will cause the metal body permeability distribution is not uniform. In eddy current testing, the change of permeability of metal will produce noise signal;

(2)Types of saturation magnetization

There are two types of magnetic saturation device used in eddy current testing. A class is composed of generic DC coil. The other kind of magnetic saturation device is made of strong permanent magnet. This scheme chooses the first class to carry out magnetization. The device can be lifted by the screw rod, and has the function of pneumatic lifting.

Marking controller

In the detection process, if you want to hit the defect position, because the probe and marking machine always there is a certain distance, so the need to delay the alarm after a certain time. Time delay can be adjusted from 0-64 seconds, with a resolution of 10 ms, up to 500 memory defects. When the instrument is working, the instrument can output the delay signal to the marking control unit in addition to the real-time sound and light alarm. When the setting time is set, the time of arrival of the time delay, the control starts the marking machine, marking out the defect. The delay signal can also be used to control the flying saw and other external mechanisms, and realize the automation of production, detection and sorting. Extend the marking of the marking machine is as follows, the customer according to their own situation to make the installation bracket.

The sound and light alarm

The sound and light alarm is connected with the real-time alarm output end of the instrument, and the power supply is switched on. When the probe passes through the defect, the display screen shows the defect, and the output signal of the instrument is given to the sound and light alarm when a period of time is delayed.

V.The photo of scene

V.The photo of scene